A 90% reduction in CO2 and Criteria Pollutants.

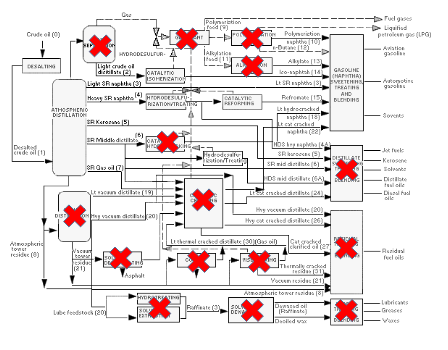

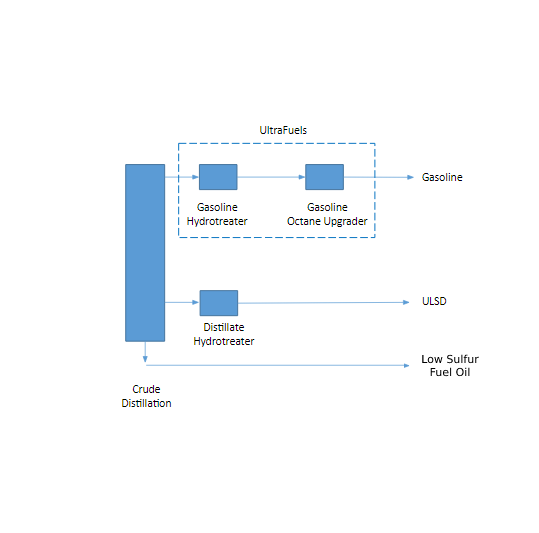

Our engineers at the San Antonio Refinery (Nustar / Calumet) performed field test runs to positively determine the capabilities and limits of the existing process equipment. Once this information was developed, we created a new processing scheme using gained knowledge from processing 100% locally produced shale condensates.

Base skid components laid out on shop floor.

Fabricated vessels ready for installation on skids.

Skids being assembled in the shop, including: equipment, piping, instrumentation.

Skids installed in the field.

Pre-wired junction boxes on skid ends.

Little to no fuel oil.

No external hydrogen required.

Simple sulfur removal.

Minimal blending.

Minimal tankage.

Minimal utilities.

Simple, efficient, easy to maintain.

Visit us

212 Pine St.

Lake Charles

LA 70601

Email us

Send email to

[email protected] and we’ll answer you shortly.

Design by Weaver Innovations, LLC.